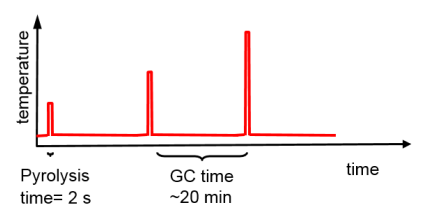

In fractionated pyrolysis the same piece of sample is pyrolyzed repeatedly at different temperatures, with intermediate periods at chamber temperature (typically 175 ºC). Since the formation rates of pyrolysis products are highly dependent on temperature this means that products that are formed easily at a lower temperature will dominate in the first pyrogram. These products will then have left the sample when the next pyrolysis takes place at a higher temperature, where other pyrolysis products in turn will appear in the pyrogram. The process can be repeated at several temperatures.

The benefit of fractionated pyrolysis is the same as for thermal desorption: different constituents of the sample may be analysed separately instead of being mixed up in the same pyrogram. Thus fractionated pyrolysis is especially suited for the analysis of complex unknown samples. Instead of making several isothermal pyrolyses at different temperatures in separate runs, which gives complex pyrograms, the same piece of sample is pyrolyzed repeatedly at increasing temperatures. This results in fewer pyrolysis products in each pyrogram and less secondary effects, making the result easier to interpret.