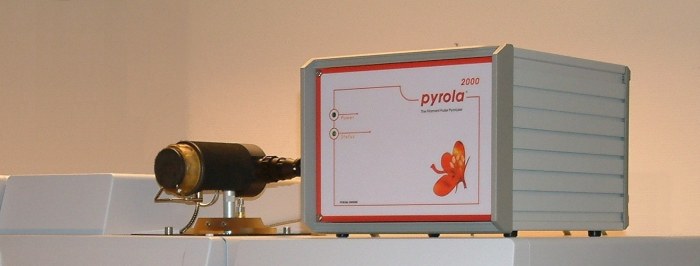

Pyrola 2000 is the current generation of Pyrola pyrolyzers. It consists of a process unit mounted on the GC, a control unit, and an optic cable transmitting light for temperature measurement to the control unit. The Pyrola 2000 is connected to a PC and is controlled by the Pyrola 2000 software.

No consumables are needed, and the pyrolysis chamber is protected from accumulating pyrolysis residues by a glass cell that is easily cleaned by heating with a micro torch. If the platinum filament eventually should break it is easily replaced and calibrated by the operator.

The Pyrola 2000 can be mounted on any brand of GC. The pyrolyzer is connected to the GC by a remote start cable, and the GC runs are controlled from the Pyrola program. The process is automated, so that the multiple pyrolyses in for example fractionated pyrolysis are started automatically when the GC has finished each run.

The process unit is very easily removed from the GC. The carrier gas is redirected by a three-way valve to go directly to the GC injector instead of going through the process unit. The quick-fittings on the gas tubes are separated, and the process unit can be lifted off the GC. It is just as easy to reattach the process unit again.The Pyrola 2000 is supplied with a wooden accessory box with sample handlers, tools, common spare parts and a cut-out compartment for storing the process unit when it is detached from the GC.

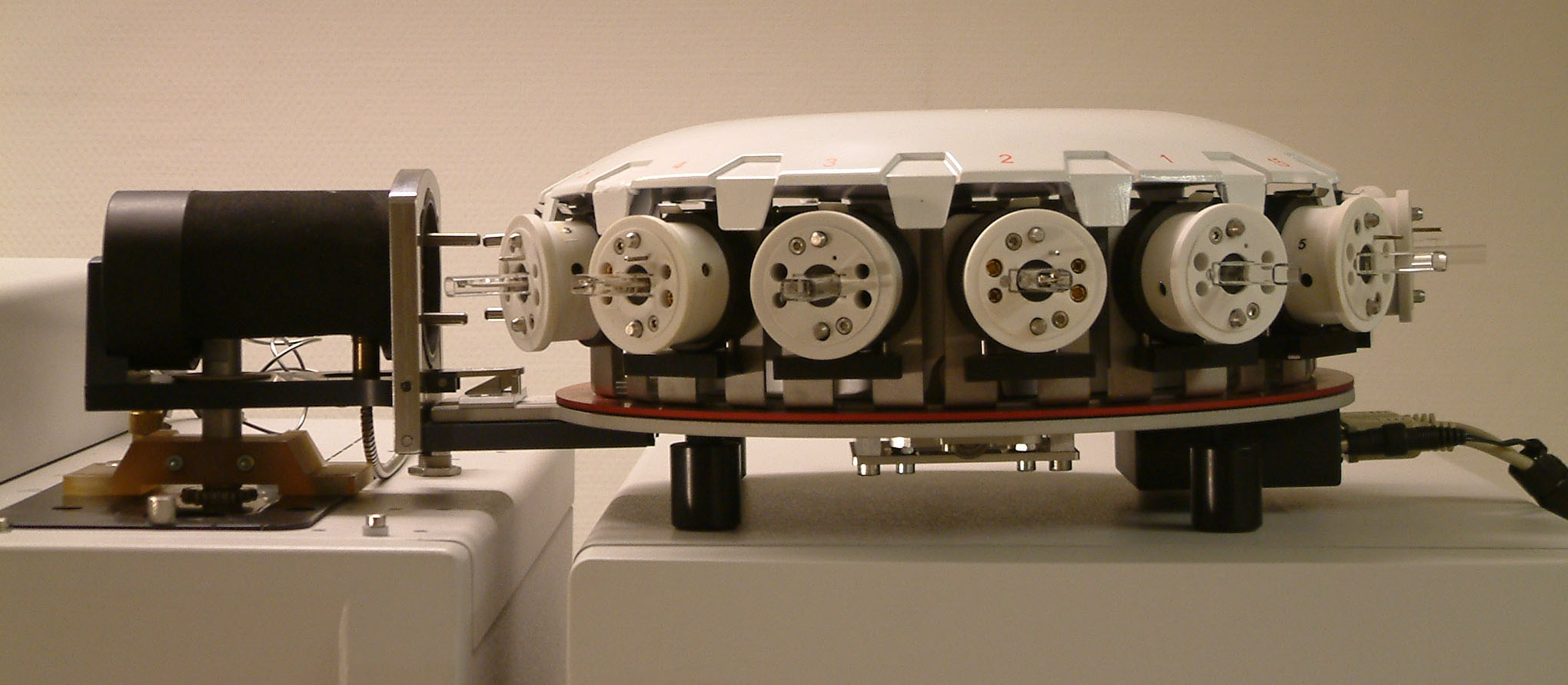

The Pyrola 2000 is also available in an automated version, the Pyrola 2000 Multimatic. It has 14 independently programmable pyrolysis probes, each having all the possibilites of the manual Pyrola 2000. It is also possible to modify an existing Pyrola 2000 system by adding the automated carousel.