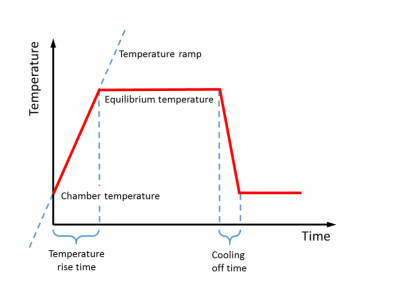

A lesser known fact of analytical pyrolysis is that the temperature rise time is just as important as the final temperature. Why? Because the key to precision is that the pyrolysis occurs at a well-defined temperature. If the temperature rise is slow the sample will be pyrolyzed already during heating, and “slow” in this context means in comparison to the half-decomposition time of the sample. Fast temperature rise time means that higher pyrolysis temperatures can be used, and the pyrolysis time can be optimised. A more detailed explanation is given in the menu under About pyrolysis.

Just as important is a fast cooling time. When the temperature drops fast the pyrolysis is halted instantly, and more information can be extracted by pyrolysing the same sample again at a higher temperature. This is called fractionated pyrolysis. In the Pyrola pyrolyzers only the filament and the sample is heated, and the pyrolysis products are instantly transferred to the separation column by the carrier gas. The temperature drops rapidly without the need for cooling gas.There is no faster way of heating a sample than to put it in direct contact with the heating element. For the Pyrola pyrolyzers the sample is put in direct contact with the filament, which is heated by a powerful electric pulse. The temperature can be raised to 1400 degrees in 8 milliseconds.