The Pyrola pyrolyzers are designed for maximum precision. As the only pyrolyzer on the market it measures the true pyrolysis temperature. Two independent methods are used: it measures the light emitted from the heated filament which is in direct contact with the sample, and it measures the resistance of the filament, which is temperature dependent. The temperature time profile is recorded for every pyrolysis, and even small variations in temperature due to sample size or exothermic or endothermic reactions during pyrolysis are registered. A small variation of the temperature time profile can change the results significantly.

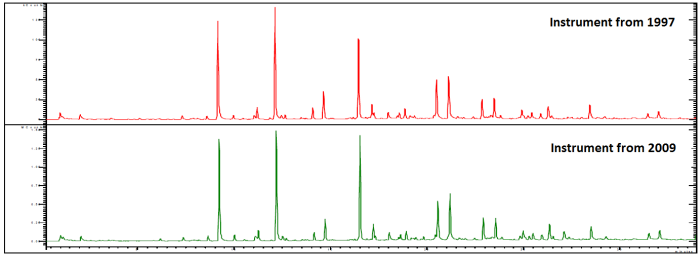

Exact control over the pyrolysis conditions is a requirement for quantitative analyses and makes it possible to compare results between different instruments and different laboratories, see the figure above.

Factors causing variations in pyrolysis conditions are minimized. The sample is placed on the filament which is flushed by the carrier gas flow. No glass tube, wool or metal cup is restricting the pyrolysis products path to the GC injector.

Special sample handlers are provided to ensure consistent sample sizes of liquid, solid and powdered samples. A quartz glass cell protects the pyrolyzer from residues, and is easily cleaned by heating with a microtorch.